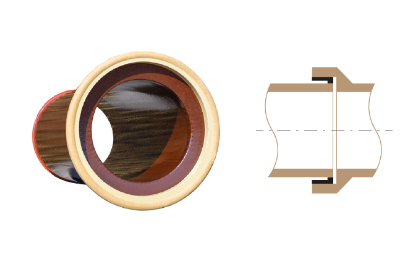

Pipes

Technical drawing

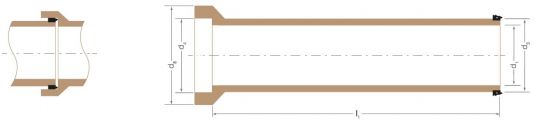

Nominal size DN 200

107 kg/piece

240

48 kN/m

Measurements

| Nominal size | Pipe diameter | Socket diameter | ||||

|---|---|---|---|---|---|---|

| DN | Inner d1 mm |

outer d3 mm |

Inner d4 mm |

outer d8 max. mm |

s1 mm |

m1 mm |

| 200 | 200 +/-5,0 | 254 +/-5,0 | 275 +/-0,5 | 360 | 27 | 70 |

Further characteristics

Brief description

For the safety, reliability and economic viability in waste water treatment we produce Cradle to Cradle certified vitrified clay pipes and fittings in excellent quality using the latest processing technology. Our system solutions meet the most demanding requirements for environmental responsibility, sustainability and service life: from the extraction of natural raw material clay through efficient processing in high-tech production plant, professional installation, more than one hundred-year-long operating life up to one hundred percent recycling potential.

Vitrified clay pipes and fittings are standardised in EN 295-1. Supplementary requirements defines the certification program ZP WN 295. All measurements - especially when connecting to other products - must be checked and depend on the specifications of EN 295 and on the certification program ZP WN 295. Subject to technical changes.

Joint systems for KERA.Base and KERA.Pro

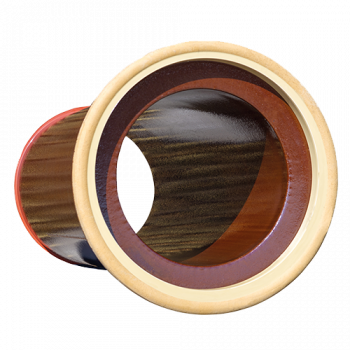

Pipes with L Joint and Joint System F

The L joint consists of a profile ring to align the spigot, and the sealing material is EPDM.

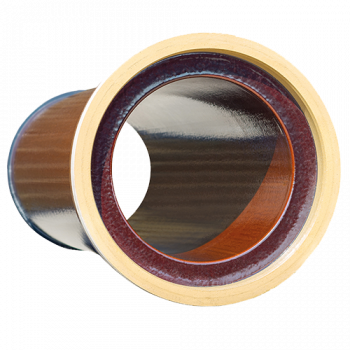

Pipes with K Joint and Joint System C

The K joint consists of a sealing element within the socket (polyurethane, rigid) and a sealing element attached to the spigot (polyurethane, soft).

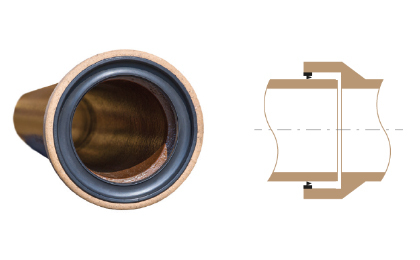

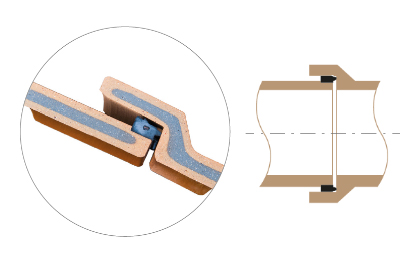

Pipes with S Joint and Joint System C

Pipe systems fitted with an S joint consist of a ceramic-rubber seal. After firing, the socket and the spigot are ground with high precision to the required size. An EPDM sealing ring is attached to the spigot during the manufacturing process.