Open trench installation

The installation of drains and sewers is regulated on a European level by EN 1610 “Construction and testing of drains and sewers.” In some areas, these regulations are additionally amended with manufacturer specifications.

Without exception, all installations of vitrified clay pipes and fittings for drains and sewers and all ensuing tests for tightness are carried out in compliance with EN 1610.

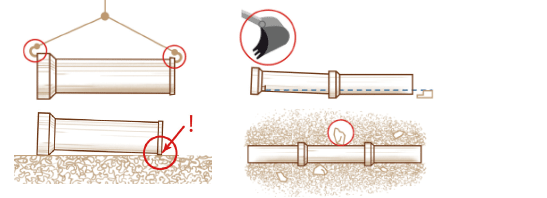

unloading, transport and storage

In cooperation with our business partners we can directly deliver to any construction site efficiently and on time using our safe reusable packaging system.

At the construction site, the pipes and fittings can be unloaded with ease and examined for possible transport damage. This examination is done by dusting the shaft ends with talcum powder. Any further transport of pipes and fittings on the construction site itself also has to be carried out with suitable machinery.

Pipes are safety stored at the construction site with the aid of the mini- in-maxipack packaging system. Individual pipes need to lie on timber beams; fittings are stored either on mesh pallets or individually upright on the socket.

INSTALLATION

As a matter of principle, only the original KeraMat lubricant that is included in every delivery may be used.

Vitrified clay pipes of small and medium diameters can be inserted with a wooden timber and a crow bar. Pipes with larger diameters are assembled with a grip hoist or winch.

When installing pipe joints, it must be ensured that the marking of the pipe crown is pointed upwards. When installing junctions in DN 350 and above, it is important to differentiate between junctions that feed in from the left and the right.

The vitrified clay pipes must be installed in such a way that they are on a level with the shaft and positioned centrally in the trench. Socket holes have to be dug for the sockets.

In case of frost, the trench floor has to be protected as vitrified clay pipes must not be installed on frozen surfaces. Installation can still take place in temperatures below 0°C as long as the necessity for slightly higher insertion forces, depending on the outside temperature, is taken into consideration. Comparably, the seals are tested up to a temperature of - 10°C.

EMBEDMENT AND SUPPORT

The bedding for the pipeline must ensure even distribution of the weight in the support area as a measure to prevent fi ssures, deformation and single-point support and hence the possibility of leakage. The bed compactness of the upper bedding layer must be at least that of the lower bedding layer.

EN 1610 describes three types of embedment; Steinzeug-Keramo recommends bedding construction type 1.

Detailed information about embedment and support can be found in our manual.

COMPACTION AND BACKFILLING

Mechanical compaction is carried out in layers of 15 to 30 cm. When using vitrified clay pipes, for grain sizes >40 mm in the first layer of the main filling to be compacted, the cover layer has to be at least 300 mm thick.

Our recommendation: If possible, use the on-site soil as filling material for the trench.

Errors to avoid