PROFESSIONAL RENOVATION WITH OUR DURA.CL ELEMENTS

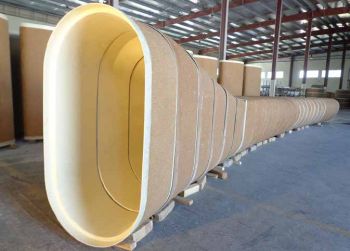

Especially with old, brick-lined sewers, the section of pipes to be renovated can include cross-sectional changes, curves and bends with different radiuses. Our DURA.CL system is made of extremely stable and highly resistant glass fiber reinforced plastic (GRP). It can be molded into almost any shape thanks to our innovative production. All parts are adapted to local conditions and individual project requirements in cooperation with our experts.

FULL AND PARTIAL RENOVATION FOR SEWERS

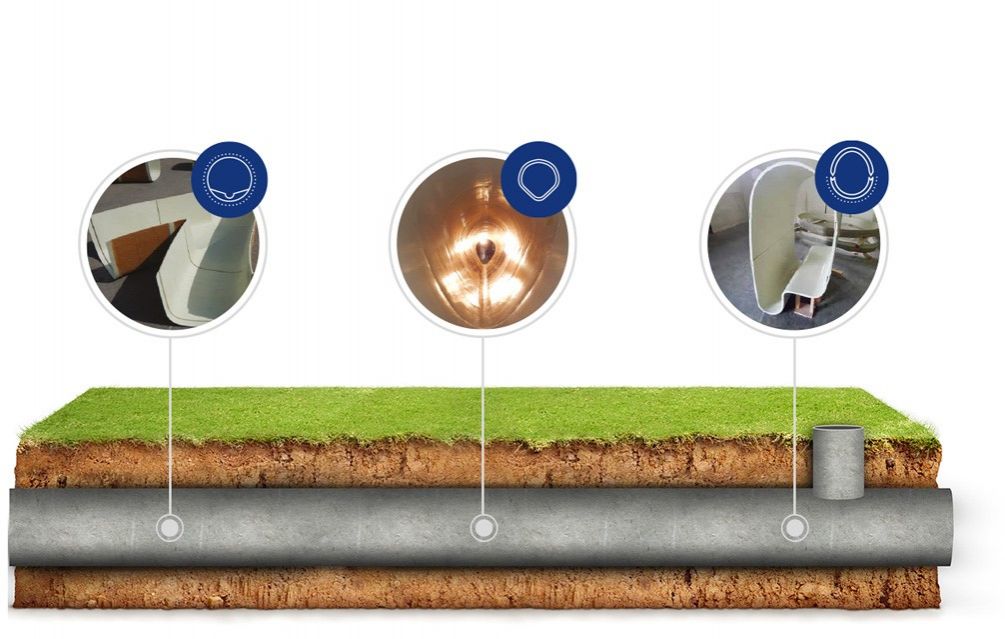

PARTIAL SEWER RENOVATION

A common example of sewer renovation is the lining of the invert with thin-walled, corrosion-resistant shells. This form of rehabilitation is particularly suitable for sewers with right angles or even acute angles. The bonding of our DURA.CL elements is straightforward and offers secure connections over the entire service life. If required, the arch of the sewer can also be lined. You will always get a tailor-made solution can be developed together with our experts.

COMPLETE SEWER RENOVATION. SINGLE-PIECE.

For extensively damaged sewers, a complete rehabilitation is neces-sary, but this can also be done to improve a new pipe. Two methods are available: multi-piece segmental lining and lining with a single pipe.

In both cases, the new sewer is constructed inside the existing one, with which it forms a strong and durable connection: the components, once they have been fitted and bonded together, are cemented to the old sewer with free-flowing mortar. No hollow space remains between them; instead, an inseparable unit consisting of the old sewer and the new sewer is created. With this renovation solution, the service life of the old sewer can be extended considerably.

COMPLETE SEWER RENOVATION. MULTI-PIECE.

Often due to either transportation problems or difficul-ties associated with access to the pipeline (e.g. entry only permitted through manholes), or in the case of a particularly large structure, it is desirable for the panels to be manufactured in two or more longitudinal sections which are site bonded above or below ground using our patented structural tongue and groove jointing system.

What makes DURA.CL so special?

![]() The general concept of DURA.CL by Channeline is that a remarkably stiff and strong panel section is con-structed, but with a relatively thin wall. The product differs from that of standard GRP hand or filament wound pipe work in several fundamental and important ways. Normal GRP pipe work consists of windings of layers of resin-saturated glass, which is impregnated with sand, achieving its stiffness by building up ever increas-ing wall thickness. DURA.CL by Channeline elements however, derives its strength and stiffness through a different method, employing the mechanics of sandwich panel design, incorporating a unique polymer and aggregate core.

The general concept of DURA.CL by Channeline is that a remarkably stiff and strong panel section is con-structed, but with a relatively thin wall. The product differs from that of standard GRP hand or filament wound pipe work in several fundamental and important ways. Normal GRP pipe work consists of windings of layers of resin-saturated glass, which is impregnated with sand, achieving its stiffness by building up ever increas-ing wall thickness. DURA.CL by Channeline elements however, derives its strength and stiffness through a different method, employing the mechanics of sandwich panel design, incorporating a unique polymer and aggregate core.

Impressionen

Technical data

Material properties DURA.CL

| Short term | Long term | |

|---|---|---|

| Flexural modulus (EN ISO 11296-4 and EN ISO 178) | ≥ 10,000 N/mm² | ≥ 5,300 N/mm² |

| Bending strenght (EN ISO 11296-4 and EN ISO 178 | ≥ 120 N/mm² | ≥ 63,6 N/mm² |

| Elongation in flexion at break (EN ISO 11296-4 and EN ISO 178) | ≥ 1,2 % | |

| Elongation in flexion at break in acid medium (ISO 10952 and ISO 10928 method A) | ≥ 1,00 % | |

| Tensile strength (on the active section) in hoop direction (ISO 8513:2016 method A) | ≥ 90 N/mm² | ≥ 47,7 N/mm² |

| Tensile strength (on the active section) in longitudinal direction (ISO 8513:2016 method A) | ≥ 45 N/mm² | ≥ 22,5 N/mm² |

| Roughness coefficient Ks | 0.03 | |

| Poisson coefficient | 0.30 | |

| Water tightness | no leaks | |

| Abrasion Darmstadt-test EN 295-3 | < 20mm after 100,000 cycles | |

| Barcol hardness NF T57-106 | > 30 | |

| Shearbond GN 4-34-02 p.6 | ≥ 1 N/mm² | |

| Thermal stability - Glass transition temperature EN ISO 11357-2 - liquid effluent - ambient air | ≥ 70°C 0°C to 35°C -25°C to +50°C |

NORME

- Nota orientativa WIS 4-34-02: WRc standard per materiali in PRFV

- ASTM D3262: Standard Specification for Fiberglass Sewer Pipes

- BS 5480: Standard Specification for Reinforced Plastic (GRP) Pipes and Fittings for Water Supply and Sewerage

- ISO 16611: Plastics Piping systems for drainage and sewerage without pressure - Non-circular pipes and joints made of glass-reinforced thermosetting plastics (GRP) based on unsaturated polyester resins (UP) - Dimensions, requirements and tests

CERTIFICAZIONI

- ISO 9001: 2015

- ISO 14001: 2015

- ISO 45001: 2018

- QB (CSTB) 26/01-296 as per Standard Avis technique n°17/15-297

- BENOR (BCCA) in accordo con la PTV BB-652-101

DURA.CL elements are made of high-quality glass-fiber-reinforced plastic, a material that has long proven itself in sewer rehabilitation.

- When being reliably watertight is top priority on your projects

- When low weight is crucial in deciding your choice of material

- When extremely long service life is a mission-critical factor

- When perfect dimensional stability under heavy loads is a must

- When you need sustained abrasion resistance under constant use

- When you have to ensure long-term, high-level chemical durability

- When frost and heat resistance are part of your project’s specifi-cations

Our consultants are happy to inform you about the strengths and opportunities offered by the DURA.CL system.

Contact now