MANHOLE RENOVATION WITH DURA.Port

If an old sewer is in need of renovation, the manholes and other structures that are also part of the system often need to be renewed, too. Renovating these elements is becoming an increasingly important task for operators. The range of stresses on manholes and related structures – for example, due to aggressive wastewater, groundwater, soil pressure or traffic – have increased steadily in recent years. Materials once considered reliable and durable can no longer withstand today's stresses. The consequences, not infrequently, are massive damage to their basic substance. The most notable stressors are:

- Hydrogen sulfide corrosion

- Defective step irons

- Leaks at connections and in the manhole wall

- Cracks and holes

- Defective berms and channels

Manholes that show such damage can no longer fulfill their function properly and have to be renovated. The DURA.PC system presents a suitable, durable solution for channels, berms and manhole walls for all common manholes. Inlets are professionally integrated into the manhole at any point using standard renovation techniques, and complex channel shapes are fitted directly on site.

Because all components can be inserted through a standard DN 600 opening, disruptive and expensive earthworks and roadwork are eliminated; required dewatering can also be kept to a minimum. The frictional connection binding the renovation components to the old manhole also increases its static load-bearing capacity.

For renovating circular manholes, we employ a method already used successfully in tunnel construction for many years. In the segmental construction method, the rising manhole rings are lined with three-part elements. The thin walls allowed by the material are particularly beneficial, allowing a maximum of free space to be retained. (e.g. a DN 1000 manhole has an inner width of 900 after renovation). Precision-designed elements are also available for other areas of the manhole.

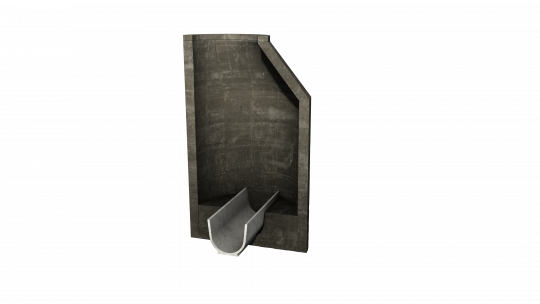

MANHOLE CHANNEL

When refurbishing channels made of cast-in-place concrete or clinker, the DURA.Port manhole channel provides a corrosion-resistant and abrasion-resistant channel.

The manhole channel is installed in the damaged floor profile. The dovetailed base in the invert region ensures secure anchoring in the manhole floor.

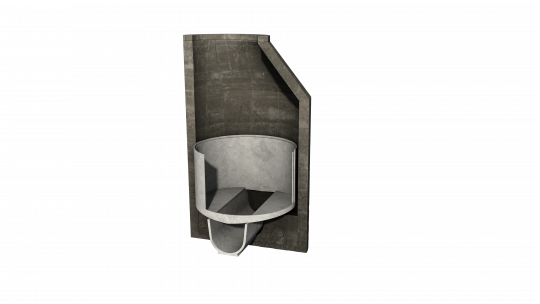

MANHOLE BERMS

For the renovation of cast-in-place concrete or clinker berms, we recommend our DURA.Port berm plates to create a corrosion-resistant and abrasion-resistant tread surface.

The panels, which consist of two sections, are inserted through the manhole opening. Bonding with the DURA.Port manhole channel and DURA.Port lining elements creates a watertight, corrosion-resistant manhole substructure.

The panels, which consist of two sections, are inserted through the manhole opening. Bonding with the DURA.Port manhole channel and DURA.Port lining elements creates a watertight, corrosion-resistant manhole substructure.

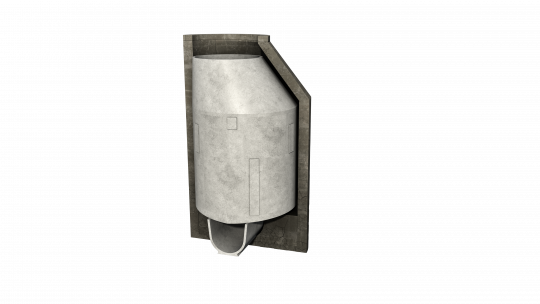

LINING

For refurbishing cast-in-place concrete manholes, our DURA.Port linings have proven their worth in constructing a corrosion-resistant and abrasion-resistant manhole lining.

The 3-part segments are brought in through the manhole opening without the need for time-consuming disassembly of the taper from the manhole.

The lining segments are connected to the berm plate and the taper with rebate joints.

Your manholes aren't circular? DURA.Port has a solution for that, too. We will be happy to advise you on choosing the optimum solution for your renovation project.

TAPER ELEMENT

A special four-part element for lining the taper rounds out our system.

As with the other parts of our system, the elements are inserted through the manhole opening. The elements are made with rebate joints to form a secure connection with the top row of lining segments.

On request, we can provide the elements ex works with countersunk holes for fastening to existing structures – please contact us for advice!

Downloads