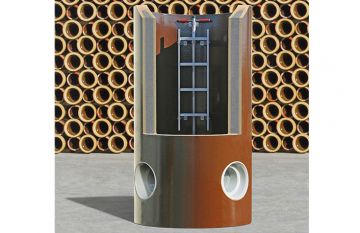

KERA.PORT MANHOLES

CORROSION-RESISTANT AND SECURE

CORROSION-RESISTANT AND SECURE

Our manholes complete our range of high-quality system solutions. Public authorities are increasingly focusing on manholes for wastewater systems. For a number of reasons, wastewater today is considerably more aggressive than it was a few years ago. The man cause of this is changes to social demographics. In addition, wastewater today has to be transported over greater distances. For treatment plants to work efficiently, it is crucial to avoid unwanted water infiltrating into wastewater systems through insecure manholes.

Range

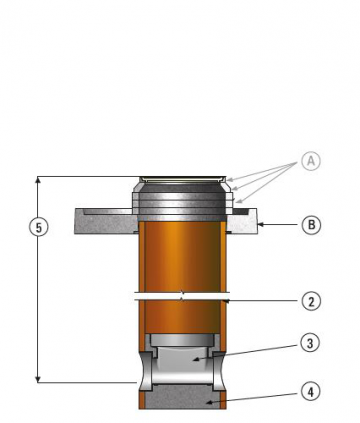

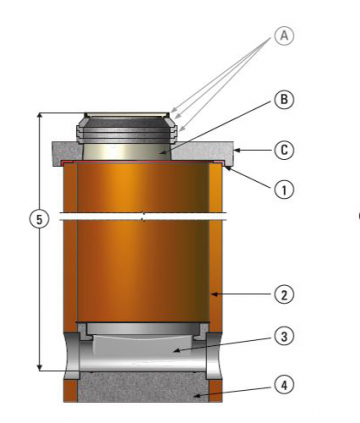

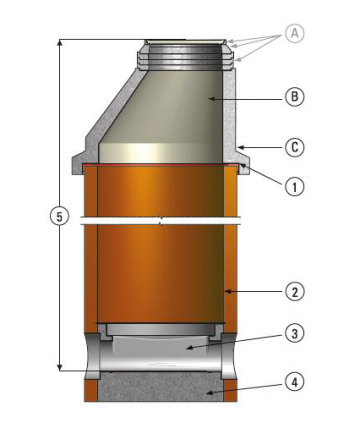

CONSTRUCTION FEATURES

- KERA.Port manholes are monolithic up to transport height

- Extension pieces are delivered with integrated joint

- Cover slabs complete the manhole; for DN 1000 manholes, an optional taper is available

- The corrosion-resistant inner lining of channel elements/cover slabs/ tapers is made of polyurethane (PU) up to DN 1000

- Structural analysis allows a possible installation depth exceeding 8 meters, documented with heavy traffic loads. Furthermore, the manholes are approved for installation within the range of railway traffic

- With their rigid, non-deformable material, the manholes are absolutely secure and won’t buckle

- Manholes with nominal sizes DN 600, DN 800 and DN 1000 are equipped with a PU bottom element as standard

- Delivery includes the manhole base unit, extension pieces and cover slab or taper

PROVEN PRODUCT CHARACTERISTICS

- Resistant to biogenic sulfuric acid corrosion

- High-pressure water-jetting resistance

- Temperature resistance to 45°C, up to 60°C on request

- Environmentally compatible, sustainable

- Durability > 100 years

- High wall thickness provides strength

- Buoyancy proofed (verifiable with online calculator in Steinzeug-Infopool)

- Retrofitting of connections is possible

- Connections are integrated into manhole wall up to DN 1000

- Channel slope gradient: 0 percent as standard*

- Manhole connections: based on 5 gon spacing smaller gradations possible

- Inlets crown-level*

- Manhole extension sections with integrated joint elements

- Cover slabs/tapers made from concrete with PU inner lining

- Upper edge of taper/cover slab DIN 4034 compatible

* individual designs possible

Product Range

Standard manholes come equipped with a one-piece PU bottom element with integrated manhole connections from DN 150 to DN 400 in the pipe wall as well as integrated buoyancy protection.