240 kg/m

160 kN/m

100 N/mm2

Characteristics

| DN 400 | |||

|---|---|---|---|

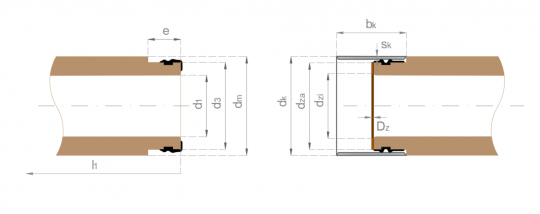

| Internal diameter | d1 | mm | 406 +/-5 |

| Spigot diameter | d3 | mm | 534 +0/-1 |

| External pipe diameter | dM | mm | 557 +0/-10 |

| Assembly depth | e | mm | 55 |

| Pipe length | l1 | mm | 984 |

| Coupling diameter | dk | mm | 540,6 |

| Coupling thickness Sk / mm | sk | mm | 2 |

| Coupling width | bk | mm | 115 |

| Thickness of thrust ring | Dz | mm | 18 |

| Jacking force pilot pipe jacking* | kN | 1700 | |

| Jacking force microtunneling* | kN | 1600 | |

Brief description

* Please note:

- The maximum permissible jacking force must be calculated in each case according to the applicable regulations, e.g. DWA-A 161 of March 2014 .

- Values given here serve only as a guide for planning

- This is subject to the condition that the effective jacking forces are continuously monitored and logged during the jacking process

- The maximum pressure of the jacking device must be limited to the permissible jacking force

Our jacking pipes with nominal sizes DN 400 to DN 600 have a new, intelligent joint system.

The joint system consists of two identical mechanical joints. The seal is pre-installed beneath the coupling on one side. The second joint and the required thrust ring are supplied separately to ensure the greatest possible protection from weather-related influences. While the thrust ring is used on the coupling side, the second joint is simply attached and fixed to the factory-machined groove at the spigot. Note that the joint, after mounting, at first projects beyond the facing of the spigot.

When the pipes are brought together – that is, when the spigot is inserted – the joint is rolled back and slides over the spigot with minimal friction.The joint material is so constructed that the use of lubricant during assembly on site is neither recommended nor necessary. This KERA.Drive joint system reliably withstands an internal and external pressure exceeding 0.5 bar.

Coupling made of corrosion-resistant stainless steel In accordance with EN 295 with pre-installed rubber joint and thrust ring made of wood composite.